Visit to the work of SIGNUS Ecovalor and the MINISTRY of ECOLOGICAL TRANSITION

RARx enters one of the main highways in Spain, the A4, demonstrating its high capacity

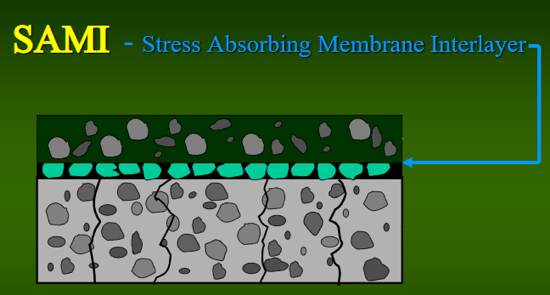

SAMI Execution

Road Rehabilitation, a complex issue

The rehabilitation of concrete roads is a complex issue, due to the difficulty of designing flexible pavements and constructive solutions that avoid the reflection of fissures and that are economically viable and lasting solutions over time.

For decades, asphalts with tire dust in high concentrations of bitumen and tire dust have demonstrated their high capacity as concrete firm rehabilitation systems.

The wet track system for the incorporation of tire dust has allowed concentrations of tire dust in bitumen, up to 18%, allowing asphalts with a content of up to 9% of modified bitumen type BMAVC.1. With these systems rehabilitations with 6 centimeters of agglomerate have been carried out with very satisfactory results. And much more economically sustainable than standard asphalt solutions with thicknesses up to 15 cm., Or with highly modified bitumen with polymers.

In the United States, since the 1970s, SAMI (Stress Absorbing Membrane Interlayer) anti-cracking systems, made with bitumen modified with tire dust, have been used as an intermediate anti-glare intermediate layer.

The appearance of RARx, as an additive system for already digested tire dust, has allowed the design of asphalt pavements with a much higher bitumen and tire dust load than those previously manufactured with wet roads. This allows to design systems with great capacity and with less layer thickness.

Work of Rehabilitation of the Concrete Firm of the A4 Highway

Thanks to the innovative and environmental nature of the technical team of the company AUTOPISTAS DE LA MANCHA, the execution of the concrete refurbishment work on the Autovía de Andalucía A4 has been carried out, which is one of the main highways with many traffic in the country.

Thus, the concessionary company commissioned SACYR CONSERVACIÓN to carry out the work.

The work has been designed and projected by the SACYR CONSERVACIÓN Special Firm Rehabilitation team, together with the technical team of the SACYR firm department and the CIRTEC technical team.

The solution has been the execution of a SAMI, on which an asphalt mixture with a content of RARx and BETUN of 11%, with 40% of RARx, in a thickness of 3.5 cm has been executed.

- CONTENT OF BITUMEN B 50/70 6.6% (S / MIX)

- RARx CONTENT 4.4% (S / MIX)

- END-OF-LIFE TIRE DUST CONTENT 2.6%

- BITUMEN CONTENT + 9.2% END-OF-LIFE TIRE DUST (S / MIX)

- % POWDER ON BITUMEN 28% (S / (B + P)

Running of the Asphalt Rolling

SAMI termination

From a technical point of view, the solution is a new milestone in Spain, since it is the first time that an anti-cracking solution has been executed using the SAMI system and asphalt mixtures with a high tire dust content.

It has allowed the entry of RARx in one of the main highways in the country, demonstrating its high capacity. And demonstrating, in turn, that the Ministry of Development and the concessionary companies of this country do not put brakes on innovation and the circular economy.

Finally, the work has allowed to design an asphalt mixture with a record of tire dust content and bitumen, which guarantees an extreme fatigue resistance.

Circular Economy and Environmental Improvement

As for the environmental aspects of the work, this solution is a clear example that the circular economy is not a philosophy, but a reality.

The work has allowed:

- Reduce the thickness of the solution, to just a monogranular layer of SAMI and 3.5 centimeters, which reduces the need for aggregates brutally compared to other solutions.

- Increase the content of tire dust in the mixture, allowing the reuse of more than 20 tons of tire dust per km of track rehabilitated (1 way), or what is the same, more than 2,000 equivalent used tires.

- Increase the life of the road over any solution, which allows to improve the life cycle of the solution.

Last Monday, July 29, the Director General of SIGNUS Ecovalor, Gabriel Leal and the head of the General Subdirectorate of Waste of the Ministry of Ecological Transition Fernando J. Burgaz visited, ratifying the interest of the state administration in the Circular Economy.

During the visit, the government’s objective of boosting the consumption of tire dust on the road, as an environmental and technical solution, was revealed.

In addition, they highlighted their gratitude to companies such as LA MANCHA HIGHWAYS, for their courage in applying new and more sustainable techniques, since it is necessary for finalist entities to be able to help the sector to evolve towards the true circular economy.