RARx means high technology servicing the road:

- It takes advantage of the simplicity of the road.

- It is capable of obtaining beter performances than that of wet roads.

Additve with similar performances to those of polymers. As pneumatc powder makes up 60 % of its compositon, this product becomes highly ecological. It is designed to be used directly in agglomerated asphalt plants.

NFU powder transforms into a factory by a wet process to be used through a dry process.

- It is incorporated in a similar way to that of fllers in agglomerated plants

- It does not produce energy cost overruns during asphalt manufacture.

- It does not decrease the plant’s productvity.

- It is incorporated directly to the asphalt plant pug mill.

- It has already been actvated previosuly so that it can be directly integrated with the mixture.

- It allows creatng thinner layers than those of standard mixtures.

- It enhances ambient conditons by producing 5 decibels “less” than a standard mixture

DOES IT ENHANCE PERFORMANCE?

Bituminous mixtures manufactured with RARX show evidence of a potental increase in fatgue resistance and, consequently, in the asphalt pot life.

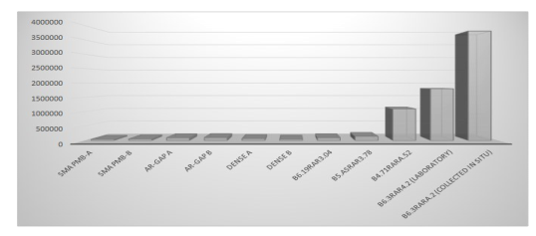

DIGESTION ASSURANCE

In the laboratory tests undertaken with RARX in mixtures with bitumen (50—70) we reach, afer 5 minutes, similar viscosity levels to those of pneumatc powder afer one hour of digeston. This clearly shows an enhancement in the performances of asphalt mixtures with RARX.